The air is released into the air chamber where it can be tapped from the top. Water flowing into the inlet draws lots of air through the angled pipes. The end of the blowoff pipe in the air chamber should be just below the minimum water level. A blowoff pipe that leads from the air chamber to beneath the water surface at the top of the outlet.

A vertical outlet pipe, somewhat lower than the inlet. A horizontal section with a raised area in the middle to hold compressed air. A vertical inlet pipe which has several angled pipes piercing its sides. If you happen to live on land that has a creek or river with plenty of drop, you could build a trompe to get huge amounts of free, dry, cool, compressed air. Posted in Engine Hacks Tagged compressed air, compressed air engine, steam engine Post navigation And this isn’t the first internal combustion engine we’ve seen converted, we’ve seen a 2-stroke strimmer engine and a rather scary lawnmower with a gas bottle boiler in the past.

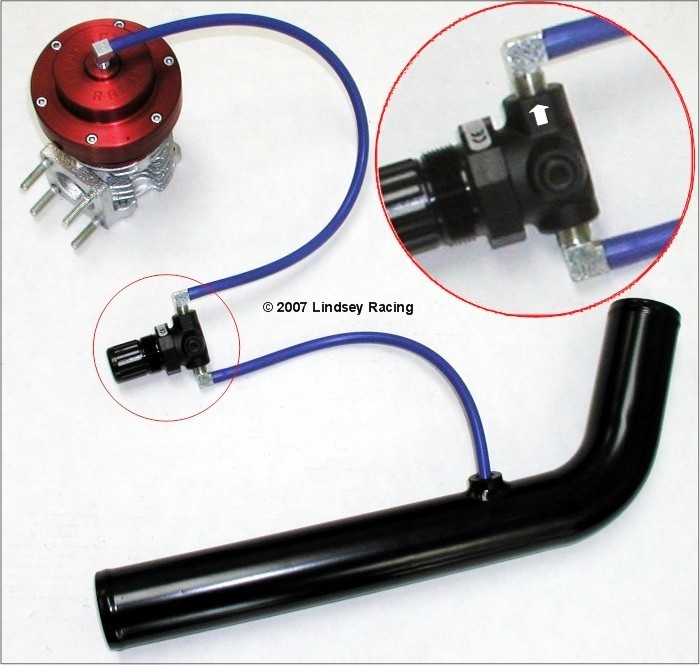

We’ve featured ’s work here quite a few times, recently with laser wire stripping and modifying a switch mode power supply. It’s an effective device, easily capable of taking more air than his compressor can supply. The video below the break shows the engine being run up after a period of storage. We might look for a harder metal than copper pipe for the guide in which it runs though. He provides a lot of detail on the sleeve valve’s construction, and it really is a surprisingly simple arrangement. The engine in question is a small sidevalve single cylinder Suffolk Punch lawnmower engine from which he has removed and blocked the valve gear, and added a sleeve valve powered by a linkage from the crankshaft and using the spark plug hole as an inlet and outlet. It’s not a steam engine because creating a safe and legal steam boiler is an expensive process, but despite this it amounts to the same thing. has a lawnmower engine which a few years ago he converted with the addition of a sleeve valve to run on compressed air. These engines are on a scale much more easily embraced by hackers and makers, and though vintage stationary engines are thin on the ground these days there are a significant number of people pursuing their construction by converting modern petrol and diesel engines to a more old-fashioned medium. But there was a period when steam engines were much more accessible, before internal combustion engines and electric motors took on the task of automating hard work you would have found small stationary steam engines in all corners of industry. A machine capable of immense power and probably with significant complexity and engineering in its construction, something the majority of us will only ever be able to see at second-hand. Our most likely exposure to a steam engine these days will probably come courtesy of a railway locomotive.

0 kommentar(er)

0 kommentar(er)